Types of Cabinet Door Router Bits with 1/4 Shank: Cabinet Door Router Bits 1 4 Shank

So, you’ve got a 1/4″ shank router and a hankering to craft some seriously impressive cabinet doors. Excellent choice! A 1/4″ shank is a versatile size, perfect for smaller routers and intricate detail work. Let’s dive into the wonderful world of router bits and unleash your inner woodworking wizard.

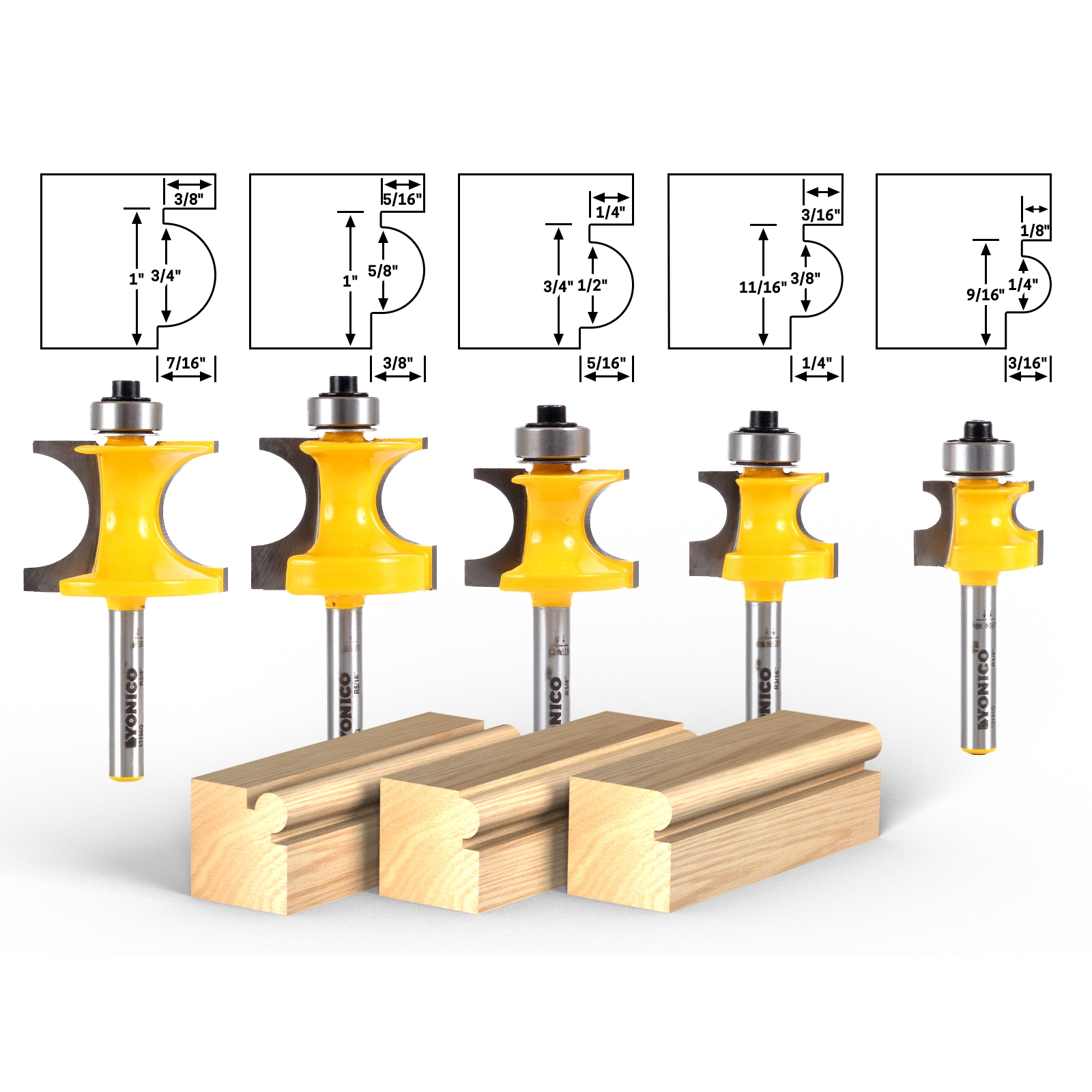

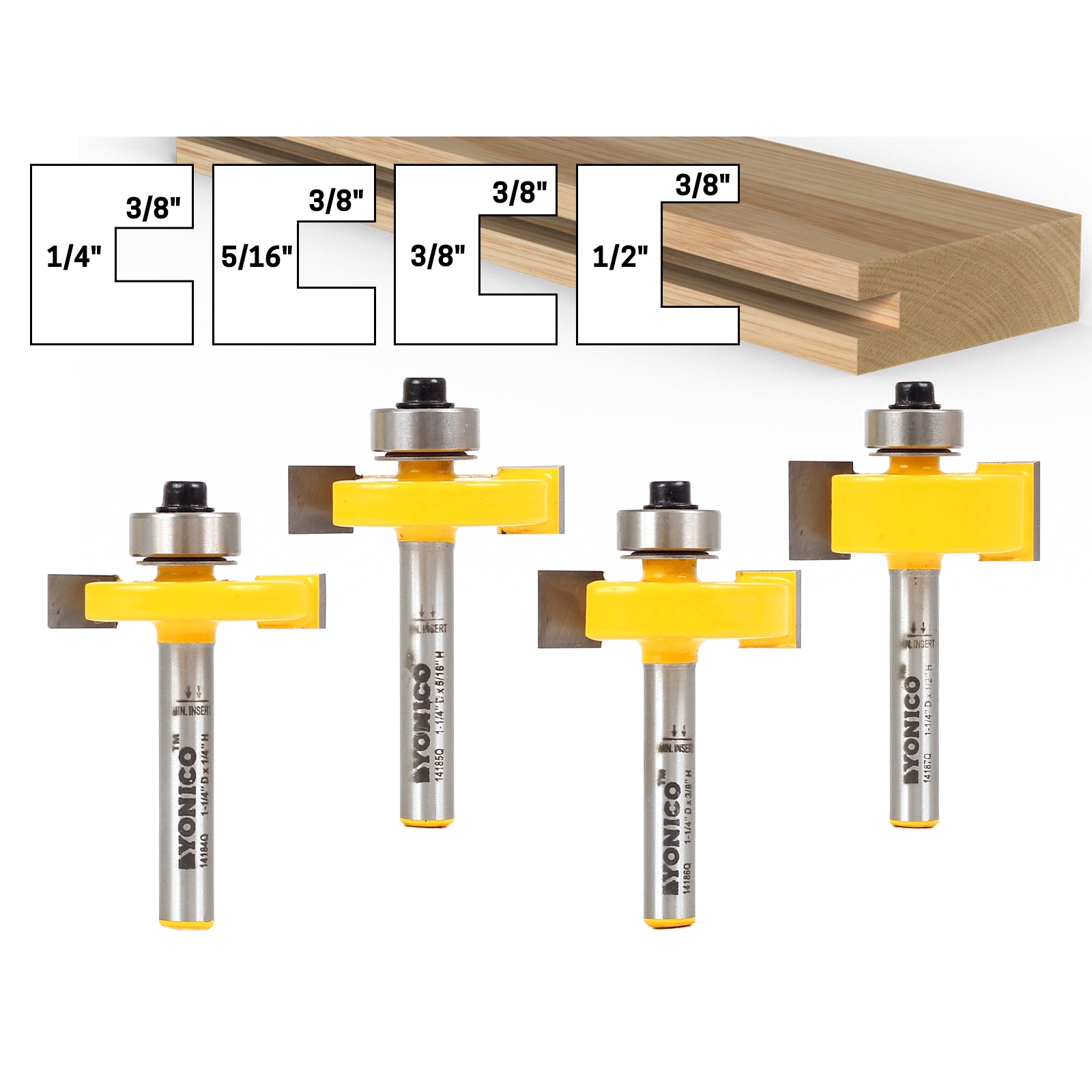

Common Cabinet Door Router Bit Profiles

Choosing the right router bit profile is key to achieving the desired look for your cabinet doors. Different profiles create different styles, from sleek and modern to classic and ornate. Let’s explore some popular options.

| Profile | Description | Dimensions (Approximate) | Applications |

|---|---|---|---|

| Raised Panel | Creates a raised panel effect, adding depth and visual interest. The panel sits proud of the frame. | Various, depending on design. Commonly 1/4″ to 3/4″ deep, with varying widths. | Traditional cabinet doors, shaker style doors. Adds a classic, timeless feel. |

| Flat Panel | Creates a simple, clean, and contemporary look. The panel is flush with the frame. | Generally, a flat bit with a width to match the panel’s desired width. | Modern cabinet doors, minimalist designs. A clean, unfussy aesthetic. |

| Ogee | Features a graceful S-shaped curve, combining concave and convex shapes. | Profile varies greatly, but usually a relatively shallow bit (1/4″ – 1/2″ depth). | Elegant cabinet doors, adds a touch of sophistication. Think fancy Victorian or Craftsman style. |

| Cove | Creates a concave, rounded profile. | Depth and radius vary. Often used to create a decorative edge. | Adds a subtle detail to cabinet doors, often used in conjunction with other profiles. |

Router Bit Material Comparison

The material of your router bit directly impacts its performance, lifespan, and the overall quality of your work. Think of it like choosing the right tool for the job – you wouldn’t use a butter knife to cut a steak (unless you’re really into that sort of thing).

Carbide-tipped bits are the workhorses of the router bit world. They’re incredibly durable, resistant to wear and tear, and can handle hardwoods with ease. They’re the “steak knives” of the router bit family. High-speed steel (HSS) bits are a more affordable option, but they tend to dull more quickly, especially when working with hardwoods. These are more like your reliable, everyday kitchen knives – they get the job done, but might need sharpening more often.

Comparison of 1/4-Shank Cabinet Door Router Bits

Here’s a table comparing four different 1/4-shank cabinet door router bits (remember, prices are approximate and can vary wildly depending on brand and retailer!):

| Bit Type | Features | Price Range | Suitability |

|---|---|---|---|

| Carbide Raised Panel | Durable carbide tip, various sizes available, precise cuts. | $15 – $40 | Traditional cabinet doors, shaker style, detailed work. |

| Carbide Flat Panel | Sharp, clean cuts, ideal for flush panels. | $10 – $30 | Modern cabinet doors, minimalist designs. |

| HSS Ogee | More affordable, good for occasional use, softer woods. | $5 – $15 | Smaller projects, softer woods, less frequent use. |

| Carbide Cove | Precise concave profile, creates a decorative edge. | $12 – $35 | Adding subtle details to doors, used in conjunction with other bits. |

Using 1/4 Shank Cabinet Door Router Bits

So, you’ve got your 1/4″ shank router bits – tiny titans of woodworking, ready to transform bland rectangles of wood into stunning cabinet doors. Let’s tackle the task with the grace of a seasoned pro (or at least the enthusiasm of one!). Remember, safety first! We’re not aiming for a trip to the emergency room; we’re aiming for beautiful, functional cabinet doors.

Cabinet door router bits 1 4 shank – Using these bits correctly involves a delicate dance of speed, precision, and a healthy respect for spinning blades. Think of it as a woodworking ballet – except instead of tutus, we have safety glasses and ear protection. Let’s get started!

Router Setup and Speed Selection

Before you even think about touching the wood, ensure your router is properly set up. This isn’t rocket science, but it’s crucial. Secure your workpiece firmly to your router table or use a sturdy clamp system on your workbench – you don’t want any unexpected leaps and bounds from your project mid-route. Choosing the correct speed is also vital; consult your router’s manual and the bit manufacturer’s recommendations. Too fast, and you risk burning the wood and dulling your bit prematurely (not a good look for a woodworking enthusiast). Too slow, and you’ll end up with a ragged, uneven cut that’ll make even a seasoned woodworker wince.

Achieving Clean and Consistent Cuts

Clean cuts are the hallmark of a skilled woodworker. To prevent tear-out (that dreaded splintering on the exit side of the cut), always route in the direction of the wood grain. Think of it as gently persuading the wood to cooperate, not forcing it into submission. For particularly delicate woods, consider using a backer board to support the wood from the underside, preventing those pesky chips from ruining your masterpiece. A sharp bit is your best friend; a dull bit is your woodworking nemesis. Regular sharpening is essential for smooth, clean cuts and a longer lifespan for your bits.

Routing a Complex Cabinet Door Profile, Cabinet door router bits 1 4 shank

Ready to tackle something more ambitious? Let’s create a complex profile using multiple 1/4″ shank router bits. Imagine a door with a raised panel, a decorative edge, and maybe even a subtle cove. It sounds daunting, but with a methodical approach, it’s entirely achievable. This will require multiple passes, carefully planning each step to avoid over-routing or accidental collisions.

- Step 1: The Raised Panel: First, use a suitable raised panel bit to create the recessed area for the panel. Make sure your depth is consistent across the entire surface to ensure a perfectly flat panel.

- Step 2: The Edge Profile: Next, use an appropriate edge-forming bit to create the decorative edge. Multiple passes may be necessary depending on the complexity of the design. Use a template if needed for extra precision – think of it as a woodworking stencil for the pros.

- Step 3: The Cove (Optional): If your design calls for a cove, carefully route the cove using a cove bit. Take your time and make several light passes to avoid tear-out and ensure a smooth, elegant curve.

- Step 4: Sanding and Finishing: Once all routing is complete, carefully sand the door to remove any imperfections. Finish with your chosen method (stain, paint, varnish) to protect and enhance the beauty of your handiwork. Congratulations! You’ve just created a stunning cabinet door!

Troubleshooting and Maintenance of 1/4 Shank Router Bits

Ah, the humble 1/4-shank router bit – a tiny titan of woodworking, capable of creating stunning cabinet doors, yet prone to the occasional meltdown (metaphorically speaking, of course. Unless you’re REALLY clumsy). Let’s tackle the common woes and keep these little workhorses humming.

Dull Bits and Inconsistent Cuts

A dull bit is like a dull knife – it’s frustrating, inefficient, and can lead to tear-out, leaving your beautiful cabinet doors looking like they were attacked by a rabid squirrel. Inconsistent cuts are often a symptom of this dullness, resulting in uneven surfaces and frustrating adjustments. The solution? Sharpening, my friend! While some bits are disposable (and let’s be honest, sometimes replacing them is cheaper than the therapy needed after a particularly bad cut), many can be sharpened with a bit sharpening stone or sent to a professional sharpening service. Think of it as a spa day for your router bits – they’ll come back feeling refreshed and ready to tackle another project. Remember to use a honing guide for a consistent sharpening angle. Failing to do so can lead to a bit that is even worse than before.

Broken Bits

A broken bit is usually a sign of user error (or maybe a rogue wood grain decided to stage a coup). This could be due to forcing the bit, using the wrong feed rate, or running the router too aggressively. Think of your router as a delicate ballerina, not a demolition crew. Gentle is the key. Avoid running the bit into hard knots or metal objects hidden within the wood (always check!). If a bit breaks, replace it immediately. Don’t try to fix a broken bit with super glue; you’ll only create a more dangerous tool. This is not a time for DIY MacGyverism.

Proper Storage and Handling

Proper storage and handling are crucial to extending the life of your router bits. Think of your bits as tiny, precision instruments that deserve respect. They’re not just bits of metal; they are the key to creating beautiful, smooth surfaces.

- Store bits in a case or organizer to prevent damage and keep them organized. A jumbled mess of bits is a recipe for disaster (and possibly injury).

- Clean bits after each use to remove sawdust and resin buildup. A quick wipe with a rag is all it takes. Think of it as a post-workout shower for your bits.

- Handle bits carefully to avoid dropping or banging them. A small drop can chip a cutting edge, ruining the bit. Remember, these bits are precision instruments, not hammers.

- Use appropriate safety equipment, such as eye protection and hearing protection. These tiny bits can cause serious injury if not handled carefully. Safety first, always.

Sharpening and Maintaining 1/4-Shank Cabinet Door Router Bits

Regular sharpening and maintenance are key to keeping your bits in top shape. This isn’t just about extending their lifespan; it’s about ensuring clean, consistent cuts that’ll make your woodworking projects a joy to create (and show off).

- Use a honing guide to maintain a consistent sharpening angle. This ensures the bit remains sharp and cuts cleanly.

- Use a sharpening stone specifically designed for router bits. Using the wrong stone can damage the bit.

- Don’t over-sharpen. A few light strokes are all that’s needed. Over-sharpening can weaken the bit.

- Inspect your bits regularly for chips or damage. A damaged bit can lead to poor cuts and potential injury.